Product description:

Pipeline pipes and petroleum casing are steel pipes formed by punching through round steel, with no welds on the surface. According to the production method, seamless steel pipes are divided into hot-rolled seamless steel pipes, cold-rolled seamless steel pipes, cold-drawn seamless steel pipes, and hot-expanded seamless steel pipes. Seamless steel pipes are classified into two types based on their cross-sectional shape: circular and special-shaped.

BN-X60N Pipeline pipe and Petroleum Casing Tube are premium-grade steel pipes engineered for oil and gas transportation, petroleum drilling, and pipeline infrastructure under high pressure and extreme temperature conditions. Developed according to API 5L, API 5CT, and ASME standards, BN-X60N pipes combine high strength, outstanding corrosion resistance, and superior weldability, making them one of the most reliable materials for modern energy and petrochemical applications.

Parameters:

Product: | Pipeline pipes and petroleum casing |

Brand: | Hengxin Zhicheng |

Standard: | API SPEC 5L, ISO 3183, GB/T 9711 |

Material/Steel Grade: | L245, L360, L450, L485, L555, etc. |

Length: | Can be 0.1m to 15m, customized according to customer requirements |

Wall Thickness: | Can be 1mm to 150mm |

OD: | Can be 4mm to 1600mm |

Surface: | Can be painted, galvanized, oiled, etc. |

Technology: | Cold drawing, hot rolling |

Port: | Shanghai Port or designated port |

Packaging Details: | Default bare pipe bundling, or packaging according to customer requirements, such as oil cloth packaging, wooden box packaging, frame packaging |

Processing Services: | Cutting, chamfering, painting, polishing, anti-corrosion, sealing |

Payment Terms: | Telegraphic Transfer |

Trade Terms: | EXW, FOB, CIF, DAP, DDP |

Delivery Time: | 10 to 35 days |

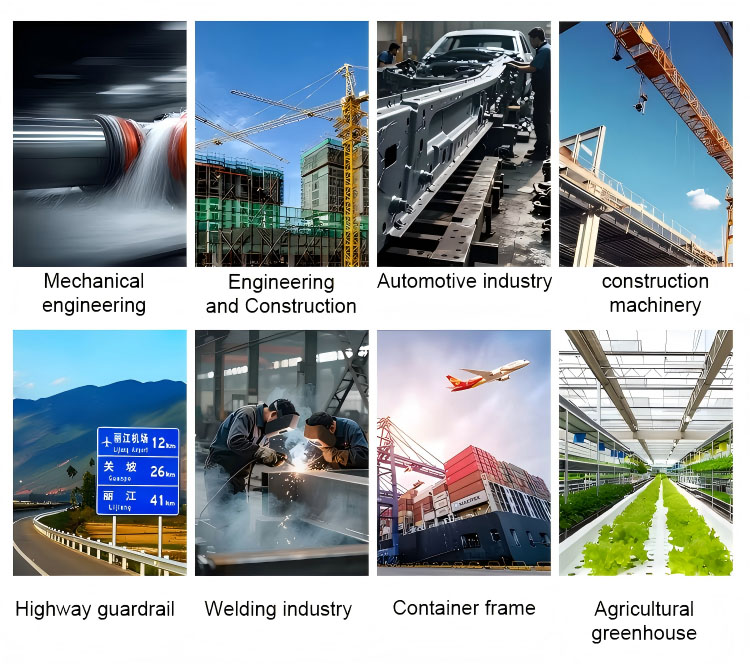

Application Fields: | Construction (underground pipelines, bridges, steel structure factories, etc.), mechanical processing (automobile parts, equipment manufacturing, etc.), electrical field (gas pipelines, petroleum pipeline pipes) |

Usage: | Used for the wellbore of oil and gas wells, as well as for the transportation of gas, water and oil in the natural gas industrial furnaces |

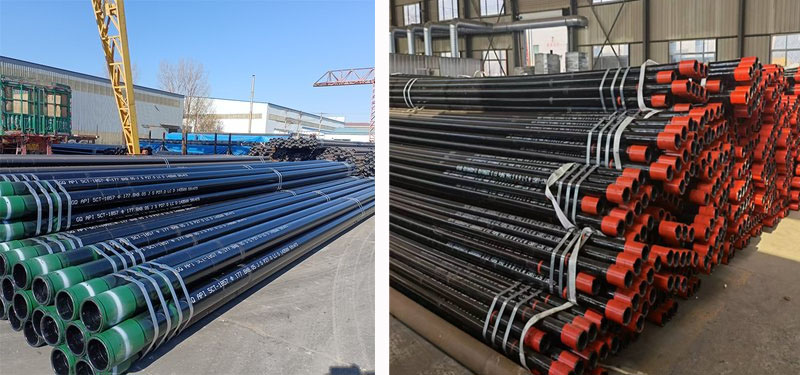

Pictures:

Product Overview

The BN-X60N grade represents an advanced high-strength pipeline steel used extensively in onshore and offshore oil and gas transmission systems. Its enhanced mechanical properties and excellent toughness make it ideal for petroleum casing tubes in drilling operations, providing long-lasting performance and structural stability in challenging environments such as deep wells, sour gas fields, and high-pressure pipelines.

Available in seamless and welded forms, BN-X60N pipes are supplied with plain end, beveled end, or threaded finishes to meet different project requirements.

Manufacturing Process

The production of BN-X60N Pipeline Pipe and Petroleum Casing Tube follows a rigorous process to ensure dimensional accuracy, high performance, and long service life:

Material selection: Fine-grain carbon-manganese steel with microalloying elements (Nb, V, Ti) for high toughness.

Forming and rolling: Hot rolling, seamless extrusion, or controlled welding for superior structural uniformity.

Heat treatment: Normalizing, quenching, and tempering to enhance yield and tensile strength.

Inspection and testing: Ultrasonic, magnetic particle, eddy current, and hydrostatic tests ensure 100% reliability.

Surface protection: Black varnished, epoxy coated, galvanized, or 3LPE/3PP for corrosion prevention.

All BN-X60N pipes undergo strict quality control in compliance with API 5L PSL1/PSL2, API 5CT, and ASME B36.10M standards.

Key Features

High yield strength and toughness: Withstands extreme internal pressure and bending loads.

Excellent corrosion and abrasion resistance: Suitable for aggressive environments and sour service conditions.

Superior weldability and machinability: Simplifies field fabrication and installation.

Stable performance under high temperature and pressure.

Dimensional precision: Ensures tight sealing and reliable connection in petroleum casing systems.

Optional protective coatings: Extend pipe life in harsh conditions such as offshore or desert regions.

Applications:

The application range of seamless steel pipes is very wide, including structures, fluid transportation, low and medium pressure boilers, high-pressure boilers, fertilizer equipment, petroleum cracking, geological drilling, diamond core drilling, petroleum drilling, ships, automotive half shaft sleeves, diesel engines, etc. Seamless steel pipes will be used to avoid leakage and other problems, ensure the effectiveness of use, and improve material utilization. It can be seen that the application of seamless steel pipes mainly reflects three major fields. One is in the field of construction, which can be used for underground pipeline transportation, including extracting groundwater during construction. The second one is in the field of machining, which can be used for mechanical processing, bearing sleeves, etc. The third field is electrical, including gas pipelines and fluid pipelines for hydroelectric power generation.

BN-X60N Pipeline Pipe and Petroleum Casing Tube are essential in the oil, gas, and petrochemical industries, serving various high-performance applications:

Oil and gas transportation pipelines: Safe conveyance of crude oil, refined products, and natural gas.

Petroleum casing and tubing: Provides borehole stability and prevents fluid contamination during drilling.

Offshore platforms: Excellent corrosion and fatigue resistance under marine conditions.

Refineries and petrochemical plants: Used in process piping, heat exchangers, and pressure systems.

Underground and subsea pipelines: Durable in environments with H₂S, CO₂, and chloride exposure.

The combination of mechanical strength and corrosion resistance makes BN-X60N a cost-effective and long-lasting choice for global energy infrastructure projects.

In stock:

Company profile:

Since its establishment in 2014, Wuxi Hengxin Zhicheng Co., Ltd. has rapidly grown into a leading enterprise in the steel manufacturing industry. We focus on the research, production and sales of seamless steel pipes, special-shaped steel pipes and hydraulic cylinders, and are committed to providing customers with high-quality, customizable products that fully meet diverse application needs.

Our products are exported to global markets such as the Middle East, South America, Africa, and Southeast Asia, and are highly trusted by large purchasers and customers in the steel industry. We always prioritize quality, reliability and customer service, and attach great importance to establishing long-term and stable cooperative relationships with customers. We provide each customer with tailor-made solutions.

We continuously promote technological innovation and improve service capabilities and production efficiency. Through an efficient online platform, you can browse our best-selling products at any time and communicate with the sales and support teams in real time to conveniently obtain the information you need. We sincerely invite partners from all countries to visit, exchange and provide guidance, and jointly explore more possible cooperation opportunities!

Certification:

Packaging and Transportation:

【Package standard】

We use steel bands to tightly package the products into hexagonal bundles. The structure is stable and not prone to deformation. Each bundle is equipped with two high-strength nylon straps to ensure the safety and convenience of the lifting operation.

To meet various maritime transportation needs, we offer a range of customized packaging options, including full coverage with oilcloth, moisture-proof wooden boxes, and high-strength protective frame packaging, to ensure the maximum safety of goods during transportation.

【Guarantee for transportation】

We offer 20-foot and 40-foot standard container transportation services. Each container can carry up to 25 tons of goods and we can accept trial orders with a minimum of 5 tons. This allows for flexible adaptation to your purchasing scale. All packaging complies with maritime shipping standards to ensure that the goods are delivered to the destination efficiently and safely.

Why us?

We focus on the research, development, production and sales of seamless steel pipes, Special-shaped steel pipes and hydraulic cylinders. We have a complete production chain and an advanced equipment system, including piercing machines, cold drawing machines, hot rolling machines, high-precision flaw detection and testing equipment. The company has passed multiple authoritative certifications such as ISO9001, API, SGS, CCS, DNV, ABS, CE, RoHS, etc., ensuring that each product complies with international standards. We are committed to providing customers with high-quality, customizable solutions to meet diverse application needs.

Relying on our own built processing base and modern workshops, combined with multiple branches and storage centers across the country, we have achieved sufficient inventory and efficient logistics coordination, significantly shortening the delivery cycle and ensuring the rapid delivery of orders.

We have established a complete service and support system. After the order is signed, the professional after-sales team can provide timely and safe on-site guidance and technical support to ensure that customers are at ease throughout the process from procurement to use.

FAQ:

1. Do you support customized design and production?

Sure. We have a professional engineering team that can conduct customized design and production with special sizes, control systems or OEM according to your requirements.

2. How fast can you deliver?

In stock sizes, it takes 3-5 days. For customized sizes, it takes 30-35 days.

3. What payment methods do you support?

We support TT payment. Generally, 30% to 50% of the payment is made in advance, and the remaining amount is paid before shipment.

4. Can you provide material certification (MTC)?

Yes, we will provide MTC to you after production is completed to ensure that the material quality meets the standards.

5. What is the minimum order quantity?

Generally, we accept trial orders. The minimum order quantity is 1-3 tons, which can be determined according to different products.

Copyright © 2025 Wuxi Hengxin Zhicheng International Trade Co., LTD All rights reserved Applications

This website uses cookies to ensure you get the best experience on our website.