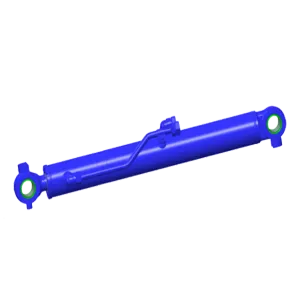

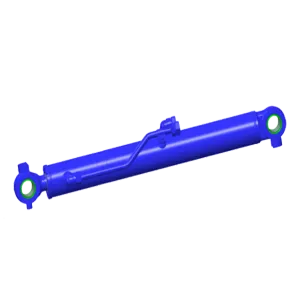

Agricultural machinery hydraulic cylinder

Agricultural machinery hydraulic cylinders are essential components in modern farming equipment, playing a critical role in enabling the efficient operation of various agricultural tasks. These cylinders are part of hydraulic systems that convert hydraulic energy into mechanical force, providing the power needed to perform heavy-duty operations such as lifting, lowering, pushing, pulling, and tilting. They are widely used in tractors, harvesters, plows, loaders, and other machinery, ensuring precision, reliability, and productivity in agricultural activities. Design and Functionality Hydraulic cylinders in agricultural machinery are typically designed to withstand harsh environmental conditions, including exposure to dirt, moisture, and extreme temperatures. They are constructed from durable materials such as high-grade steel or aluminum, with components like pistons, rods, seals, and barrels engineered to ensure longevity and resistance to wear and tear. The cylinders operate by using pressurized hydraulic fluid, which is controlled by valves and pumps, to move the piston within the cylinder. This movement generates linear force, which is then transferred to the machinery’s moving parts, enabling precise control over operations like adjusting the height of a plow or tilting a loader bucket. Types of Hydraulic Cylinders There are several types of hydraulic cylinders used in agricultural machinery, each suited to specific applications: 1. Single-Acting Cylinders: These cylinders use hydraulic pressure to move the piston in one direction, with an external force (such as gravity or a spring) returning it to its original position. They are commonly used in simpler applications like lifting mechanisms. 2. Double-Acting Cylinders: These cylinders use hydraulic pressure to move the piston in both directions, providing greater control and versatility. They are ideal for tasks requiring precise movements, such as steering or adjusting implements. 3. Telescopic Cylinders: These multi-stage cylinders are used when a long stroke is required in a compact space, such as in dump trailers or grain augers. Key Features and Benefits Agricultural hydraulic cylinders are designed to deliver high performance and reliability. Key features include robust construction, corrosion resistance, and the ability to handle high pressures and loads. They also offer smooth and precise operation, which is crucial for tasks like planting, harvesting, and soil preparation. Additionally, modern hydraulic cylinders are designed for ease of maintenance, with replaceable seals and components that extend their service life. Applications in Agriculture Hydraulic cylinders are integral to a wide range of agricultural machinery. In tractors, they power the three-point hitch system, allowing farmers to attach and adjust implements like plows and seeders. In harvesters, they control the movement of cutting blades and conveyor systems. Loaders and backhoes rely on hydraulic cylinders for lifting and digging operations, while sprayers use them to adjust boom heights for precise application of fertilizers and pesticides. Conclusion Agricultural machinery hydraulic cylinders are indispensable in modern farming, providing the force and control needed to perform a variety of tasks efficiently. Their durability, precision, and versatility make them a cornerstone of agricultural productivity, helping farmers meet the demands of modern agriculture while reducing manual labor and increasing operational efficiency. As farming technology continues to evolve, hydraulic cylinders will remain a critical component in the development of advanced agricultural machinery.

Products

Category:

-

Agricultural machinery hydraulic cylinder

Category:

Hydraulic cylinder

Browse number:

689

Number:

Release time:

2025-09-08 22:07:14

Hydraulic cylinders convert hydraulic energy into mechanical energy, and the linear reciprocating motion (motion or swing) of hydraulic actuators. Hydraulic cylinders can perform operations such as lifting, bending, straightening, shearing, squeezing, welding, lifting, stretching, stamping, stamping, steel structures, bridges and buildings, engineering machinery, etc. It is a specialized tool for pressure vessels and can be used for direct pressure testing. Its structure is simple and it works reliably. It can be used to achieve reciprocating motion, so it is widely used in hydraulic systems of various machinery.

News

Category:

No search results found!

Case

Category:

No search results found!

Video

Category:

No search results found!

Download

Category:

No search results found!

Job

Category:

No search results found!

Featured Products

No search results found!